Accessories

We are here to help you choose the ideal pump

Vacuum pumps show a drop in performance according to altitude, considering the measurement at 50 kpa. Consider loss of 1% vacuum for every 100 meters of altitude

Example

| 1000 mts = 10% |

| 1500 mts = 15% |

| 3000 mts = 30% |

| and so on |

Flowmeter

Technical Information:

How to use

Open and close the faucet of the vacuum gauge to zero it (Balance the internal and external pressure) Check the identification plate on the pump to be measured and adjust the flow meter

Example

On the 450 l pump identification plate, place on the flowmeter, on the coarse adjustment ring = 1 and the fine adjustment disc = 6. Turn on the pump and see on the vacuometer it should mark 50 kpa. If this marking does not occur, we must adjust the flowmeter by opening or closing the regulators until the vacuometer marks 50kpa. conversion: FINE ADJUSTMENT + THICK ADJUSTMENT = TOTAL FLOW

Composition

| 1 cast aluminum body |

| 1 stainless steel vacuum gauge lubricated with glycerin |

| 2 rubber fitting cones |

| 1 rubber disc for fine adjustment |

| 1 rubber ring for coarse adjustment |

| Rubber disc for fine adjustment measurement |

| (1 hole is worth 50 L / min) |

| 2 for 50 L, 4 for 100 L, 6 for 150 L, 8 for 200 L |

| Rubber ring for thick adjustment measurement |

| (1 hole is worth 300 L / min) |

| 1 for 300L, 2 for 600L, 3 for 900L, so up to 14 for 4200L |

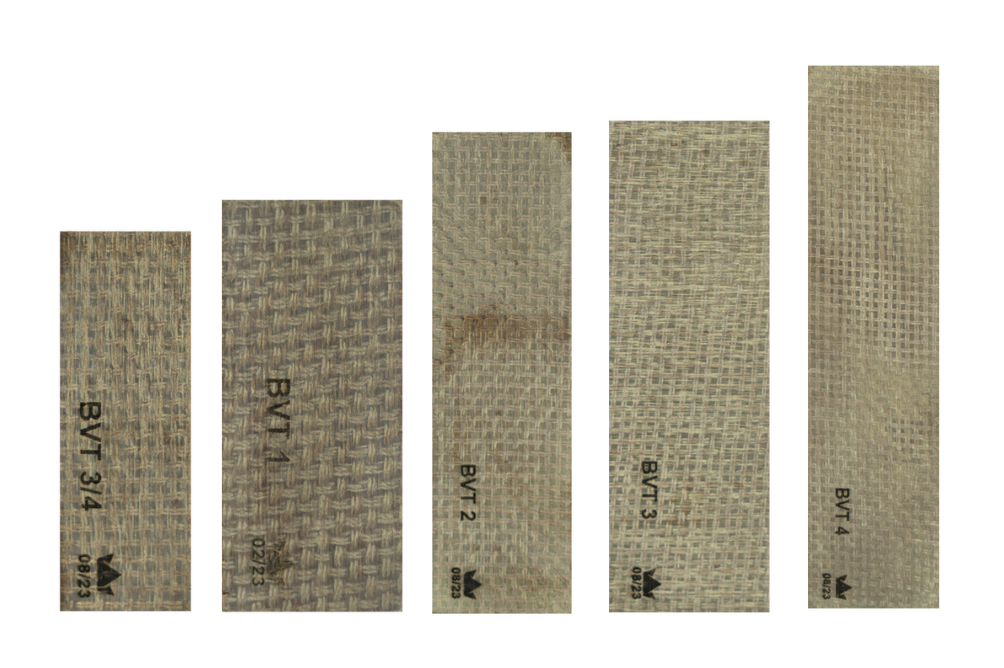

Reeds

Reeds BVT 3/4, BVT 1, BVT 2, BVT 3 and BVT 4 de Aramida

produtos.regulador

Vacuum meter at the tip of the ceiling

Wick Suction Lubricator

Vacuometer

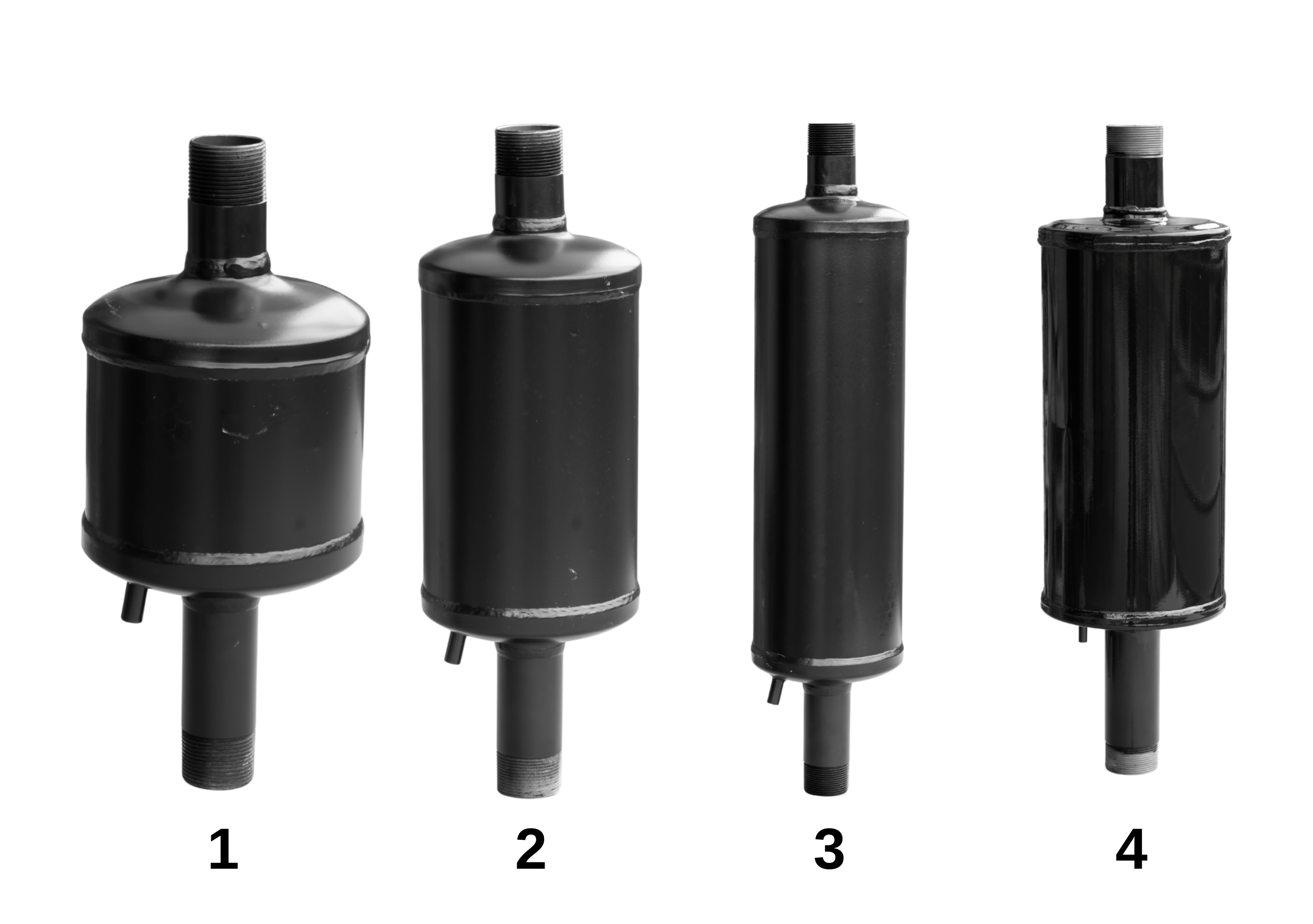

Silencer